KPM 1036 Fully automatic stationary Multilayer Machine (Pallet Free)

Dimensions 16000х7000х4150 mm.

Performance: 144 pallets per hour.

Size of the process pallet 1300х1150х40 mm.

Number of products on a pallet:

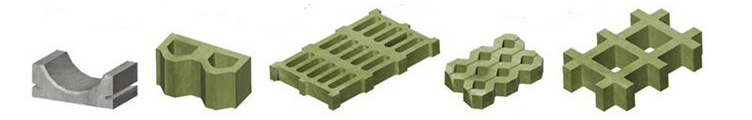

Paving slabs 200х100х60 mm. - 54 pcs. (1,08 m2)

Block 400х200х200 mm. - 12 pcs.

Kerbstones 1000х300х150 mm. - 6 pcs.

Kerbstones 1000х200х80 mm. - 8 pcs.

Vibro table size 1150x1050 mm.

Number of bottom vibrators 4 pcs.

Number of top vibrators 2 pcs.

Volume of a hopper for concrete mix 2000 l.

Maximum height of products 400 mm.

Minimum product height 40 mm.

The volume of hydraulic installation 1200 l.

Forming modes Automatic, manual.

kerbstones

1000.300.180 mm 5500 pcs.

1000.300.150 mm 5760 pcs.

1000.200.80 mm 9216 pcs.

Paving slabs

200.100.60 mm 1244 m2.

200.100.80 mm 1200 m2.

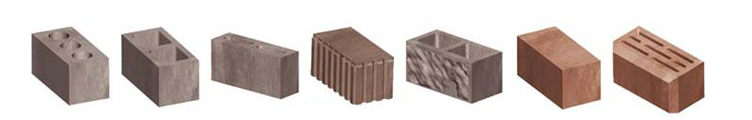

Blocks

400.200.200 mm 13824 pcs.

400.100.200 mm 26000 pcs.

Concrete block machine with two hopper for concrete

Accumulator of empty pallets

Conveyor from the accumulation of empty pallets to the concrete block machine

Conveyor from a concrete block making machine

Electrical cabinet

Software

Mold

Optional equipment

clamping forklift*

КРМ 1036 is a new-generation concrete-forming machine with a layer-by-layer forming principle.

The main distinguishing feature of this model, which gives important advantages, is its forming method. The forming process runs not on the technological pallet, but on a special metal table, and from this table the products are then placed on the technological pallet.

This forming method offers the following advantages:

1. The layer-by-layer forming process allows the tiles to be stacked on a pallet in 8 rows, which allows using fewer technological pallets for paving tiles production, and the most important advantage is that these technological pallets can be made from ordinary plywood. They are no longer involved in the forming process and there are no special requirements for their strength and wearing capacity. This advantage significantly reduces the production costs of technological pallets.

2. The cement consumption decreases, and the cost of production also decreases.

3. Molding on a special table - small-piece concrete products are given a shape, then the products are layered on the pallet;

4. The product has an ideal geometry. The products have a higher packing ratio if compared with the products formed on a wooden pallet.

The powerful vibrating table 104 КN with forced cooling is fully controlled by an automatic control system with Omron electronics. The touch screen menu allows to change the forming parameters, including the frequency of the vibrating table’s motors, pairwise, and, correspondingly, the amplitude of the vibrating table.

There is a possibility to quickly change a form, because there is no bolted connection of the form to the press, the form is fixed with the use of pneumatic clamps. The form can be replaced in less than 5 minutes.

In addition to the advantages described above, КРМ 1036 also has increased pallets dimensions and is designed to form six stone curbs simultaneously. All these advantages make the КРМ 1036 model one of the most production-efficient lines in its segment.

КРМ 1036 is supplied with two hoppers, two conveyors and one storage elevator.

A double-hopper line allows to produce units with different fillers, which allows to reduce the cost of the product and to use the coloring agent with higher efficiency.

The proposed line will perfectly suit those who want to significantly improve production rate and to increase business efficiency at the same time by reducing the cost of production and other operating costs.

Video